This page shows information relevant to our sites in South Australia and western Victoria. Visit bunge.com/Australia for information about delivering to Bunge’s Western Australian sites.

We’re ready to support you through the 2025/26 season

As part of our harvest preparations, we have:

As part of our harvest preparations, we have:

| Invested $65 million in our supply chain | 6 million tonnes of forward shipping capacity booked | 1500 harvest workers onboarding |

| Improving efficiencies through our annual capital expenditure and maintenance investment, including new and upgraded drive over hopper stackers, front end loaders, weighbridges and bunkers. Read more. | Reflecting the strong demand from buyers for new season grain delivered to the Bunge network. | Joining our experienced permanent and ongoing employees to help receive your grain. |

Following the successful combination of Bunge and Viterra in July, we’re continuing to transition to the Bunge name and brand.

You can continue to engage with our team and utilise our sites and services as you have in the past and can expect the same high level of service from us.

We’re looking forward to working with you again this harvest.

Key information for delivering to our SA and western Victorian sites

Segregation plans

We have updated our 2025/26 segregation plans based on farmer feedback and our planting survey results.

View our segregations on our website or on the Bunge app.

We will continue to work with farmers to understand quality and yield expectations, to ensure our planned segregations match what will be delivered.

Increased total defective grain tolerance for A grade lentils

We’ve increased the total defective grain (TDG) tolerance for A grade lentils, allowing you to achieve a higher grade.

Lentil deliveries with total defective grain between 4.5 and 5% will now achieve A grade instead of B grade, meaning you can achieve a higher value for their delivery and no tonnage deductions will be applied.

We have also reduced the tonnage deduction to 1% instead of 1.5% for B grade lentils with total defective grain between 5.1 and 6%.

Deliveries also need to meet all other receival standards for the relevant grade.

Our continued investment in our supply chain has enabled us to change how we store lentils and increase our service offering to farmers, while continuing to meet buyers’ quality requirements and maintain market access for SA and western Vic grain.

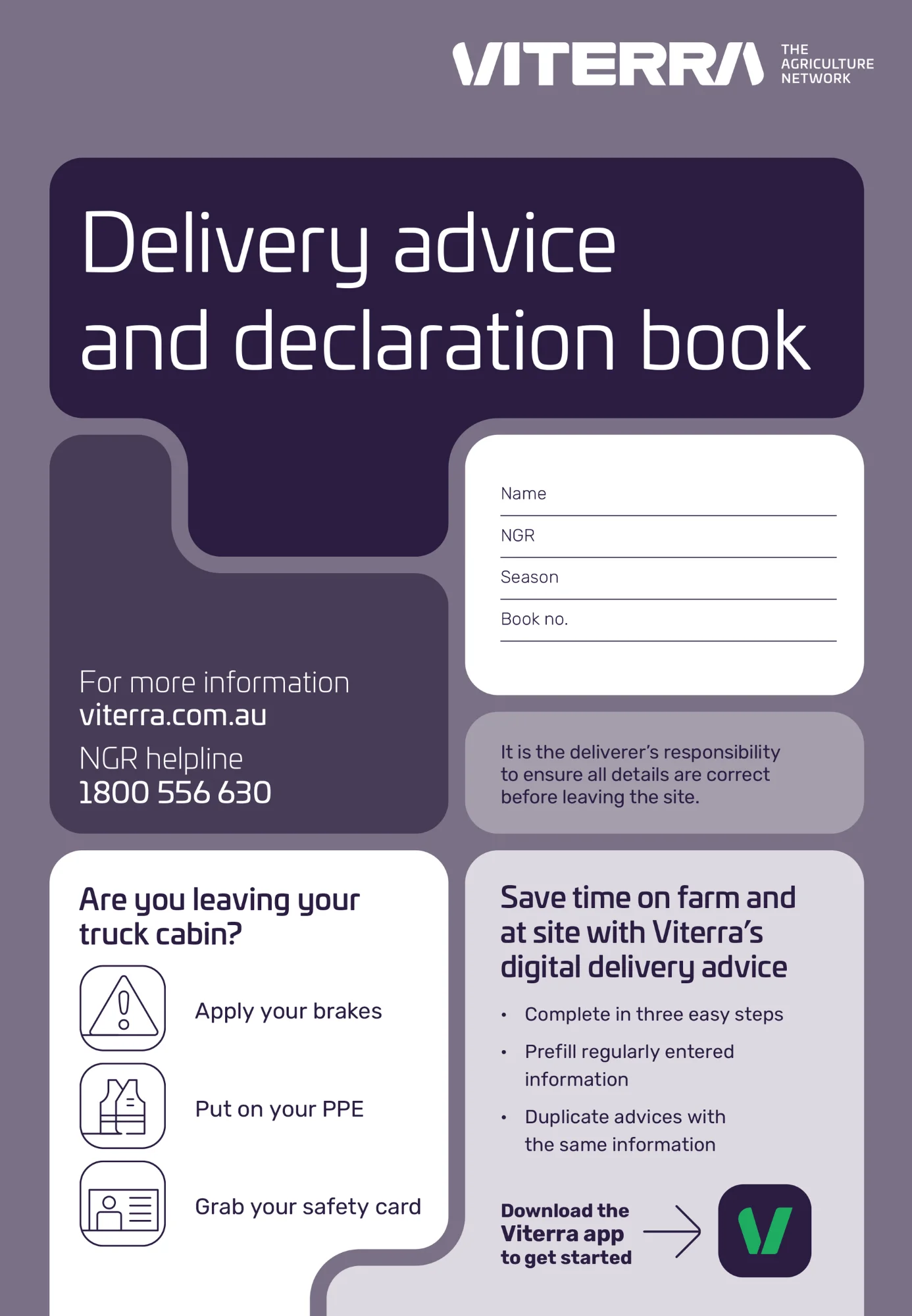

Delivery advice and declaration book

There are no changes to our delivery advice and declaration book for this harvest. You can continue to use any remaining Viterra books.

If you are delivering canola, you must use the latest version pictured.

You can continue to use older versions for other commodities, but if you select a cash or pool option, we will warehouse your grain.

Changes to wheat variety classification

We follow Grains Australia’s wheat variety master list to determine our variety list, if you deliver a variety that is not on our list, the highest grade you can achieve is SFW1 feed grade.

Information about our transition to the Bunge name and brand

South Australian and western Victorian storage and handling operations

On 21 August, Viterra Operations Pty Ltd changed its name to Bunge Operations Pty Ltd.

Aside from the name, there are no changes to the surrounding details of the legal entity.

There are no changes to the operations of our storage and handling network in South Australia and western Victoria, including for deliveries to site.

You can continue to engage with our team and utilise our sites and services as you have in the past.

Information on the Bunge and Viterra websites

While we integrate, the Australian Bunge and Viterra websites both remain active for the coming harvest.

Where to find information about:

| Delivering to our South Australian and western Victorian sites | Selling to Bunge |

|

Stay on viterra.com.au for information including:

|

Visit bunge.com/Australia for information including:

|

Updates to our digital services

The Viterra app is now the Bunge app

We have updated the name of our app from Viterra Australia to Bunge Australia, as well as its design, following the combination of Bunge and Viterra in July.

You can continue to access the same information on the Bunge app as you have previously, including logging into Ezigrain, plus some new features based on your feedback.

Update your app

Bunge Australia on the Apple App Store

Bunge Australia on Google Play

If you have automatic updates turned on, the Viterra app may have already updated to the Bunge app.

Ezigrain

We have updated the design of Ezigrain to reflect the Bunge brand.

You can continue to access Ezigrain as you have previously. There are no changes to the URL or your login details.

Delivering value with $65 million invested in our supply chain

This year we’ve invested $65 million across our SA and western Victorian network as part of our annual capital expenditure and maintenance investment. We invest where it provides the greatest value to our customers by enhancing efficiencies and increasing reliability.

As part of this, new plant and infrastructure will be at sites to improve the delivery experience. This includes four new drive over hopper stackers across our network, a second inwards weighbridge at Tailem Bend, and an additional classification office at Wudinna to support lentil deliveries.

At Port Giles, we have upgraded bunkers to provide additional storage capacity. We have also made structural upgrades to bunkers at sites including Wallaroo, Snowtown, Werrimull, Kimba, Lock, Cummins and Wudinna.

Across several sites we have completed roadworks and made upgrades to existing infrastructure, such as shed sealing at Keith, which ensures we can continue to provide a sustainable and efficient network for the long term.

Stage 1 of $50 million upgrade to Wolseley unveiled ready for harvest

We recently celebrated the opening of our Wolseley site ready for 2025/26 harvest following significant upgrades. This was an exciting milestone in our $50 million project which aims to improve safety, expand the site and create efficiencies and value for our farmer and buyer customers and the local community.

We were pleased to unveil the significant works we have done as part of stage 1 of the project which focuses on improving the farmer delivery experience, with additional bunker storage, new classification centres and weighbridges, larger marshalling area and better roadways, as well as new water basins.

We also showcased the work that has begun for stage 2, which involves building a rail track around the site and installing fast rail loading bins to help make grain transport to port more efficient, reduce truck movements and cut carbon emissions.

This investment is in addition to the $65 million we invested across our network this year in capital expenditure and maintenance.